7 Reasons you have a DIY peeling epoxy floor

The largest criticisms concerning epoxy is a peeling epoxy floor not long after application or inside a year of it being put in. Many that have an interest in epoxy garage flooring do not realize is that 99% of these complaints do not involve a defective epoxy product. So, given that the epoxy is good, what causes epoxy coated garage floors to peel up?

What is interesting to notice is the bulk of complaints regarding epoxy garage floors are from DIY applications. There’s a legitimate reason for this. The typical DIY installer is not very intimate with the process of an epoxy floor installation garage floor epoxy to start with. After you couple that with the very fact that several of the cheap epoxy floor kits build application sound as simple as rolling paint on a floor; you have currently the potential for failure.

“I followed the instructions on the box exactly. Why do I have a peeling epoxy floor?”

Most of these complaints begin with the above statement. The worst part is that they probably did follow the instructions exactly as stated on the box. That, however, does not mean that what instructions described actually prepped the concrete properly.

We don’t know Agent Purple or the installer that installed this floor. But this is very indicative of a bad, really bad, peeling epoxy floor. Epoxy coatings will not fix a bad concrete surface.

What? How could this be?

Don’t worry, the explanation is coming right up.

The main reason for a peeling epoxy floor is poor preparation of the concrete surface. This is due to a variety of factors.

Epoxy needs a clean and porous surface in order to achieve a mechanical bond to the concrete. If you don’t have that, it’s almost guaranteed that your coating is going to fail at some point.

As an example, lesser expensive epoxy kits generally come with safe to use, biodegradable solutions that are supposed to clean and etch the concrete simultaneously in order to provide the proper surface profile for epoxy. In many cases however, these do not work well.

But how is the DIY installer to know?

If you don’t know what the surface should look like when the concrete prep work is done, how it should feel, and how to test it, then it really is a gamble whether or not your epoxy coating is going to peel or not.

Without any more ado here are the reasons for your DIY peeling epoxy floor.

Click the button below to choose

your date and time!

Epoxy is a very tenacious and tough coating to remove when applied properly. That is why there are so many successful, long lasting epoxy garage floor coatings that people absolutely love. Just about every problem you may have heard about epoxy flooring can be avoided by paying attention to the details. With that in mind, we have listed the seven most common reasons for epoxy peeling up along with the solutions on how to avoid them.

1. Poor Surface Profile

As we stated earlier, a poorly prepared concrete surface is the main culprit to epoxy peeling. The number one problem associated with that is a bad surface profile. Surface profile is the roughness and porosity of the concrete that allows for the mechanical bond of the epoxy.

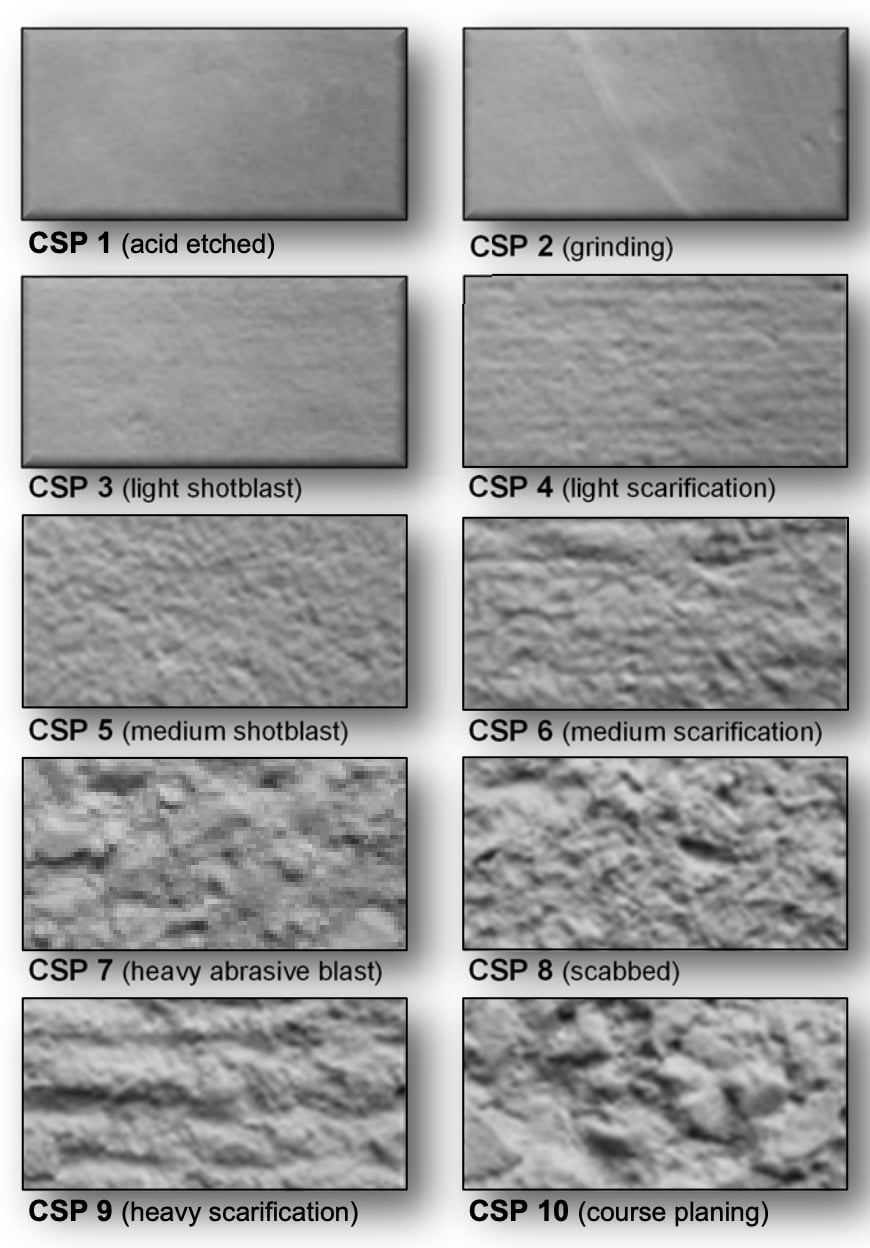

Concrete Surface Profile (CSP) is the measure of the average distance from the peaks of the surface to the valleys as seen through a cross-sectional view of the concrete surface. The standards are rated 1-10 with 1 being the smoothest and 10 being the roughest.

Most epoxy requires at least a CSP 1 or CSP 2 profile to achieve the proper mechanical bond

In order to obtain the correct surface profile for epoxy, you need to acid etch the concrete at the very minimum. Grinding the concrete is the preferred method, but it’s not always feasible for the average DIY install. You can read more about grinding versus acid etching here.

Profiling the concrete exposes the pores so that the epoxy can sink in a little to get the bite it needs to adhere as well as it does. If not done correctly, the epoxy will not adhere well and can start to peel at some point after application.

Once the concrete is profiled correctly, it should have a lighter appearance and a rougher texture to it that is similar to 100 grit sandpaper. Test it by dripping some water onto the concrete in various areas. The surface should immediately turn dark and absorb the water in less than a minute.

Beware of the clean and etch solutions that come with the lesser expensive, single coat garage floor epoxy kits. Many times these solutions are not effective enough to create the proper surface profile.

Note: New concrete or concrete in a brand new home needs profiling just as much if not more than older concrete. The effects of troweling the concrete to make it smooth create excess laitance (fine particles that washing does not remove) and an ineffective mechanical profile for epoxy to adhere to.

2. Moisture

The second most common problem associated with the peeling of epoxy garage floors is moisture in the concrete.

Water vapor cannot pass through epoxy. If you have moisture under any part of your slab that is below grade, the hydrostatic pressure that is created from water vapor being trapped under the epoxy coating can create enough force to lift the epoxy right off the surface.

Inspect your floor for signs of moisture. Efflorescence is the very first sign that you may have a moisture problem. So are dark spots on the floor.

If your slab is below grade on any side then it’s imperative that you do a simple moisture test first before starting an epoxy floor project.

3. Oil and Contamination

Once you have achieved the correct surface profile for epoxy, it’s important to check that any oil stained areas that were previously cleaned are absorbent and not repelling water. These are areas that you will want to check with the water drop test.

It’s not uncommon for a previously oil stained area to be darker in color than the surrounding concrete. As long as it absorbs water, then it will absorb epoxy and provide for good adhesion.

Other contaminants such as silicone from tire dressing products and polymer compounds that leach out of warm tires will not allow epoxy to adhere either. Be sure to perform a water drop test around the areas where the car tires sit as well.

Acid etching will not remove silicones and tire polymer residue. If you acid etched the concrete and these areas do not pass the water drop test, you will need to grind the concrete to remove the residue.

Note: Acid will not remove oil stains or clean heavy grime off of concrete. Acid needs to react with the free lime in concrete in order to work. If the concrete has a thin film of oil or grime on the surface the acid will not react and you will have a poor surface profile.

4. Acid Etching Residue on the Surface

When you acid etch your garage floor the acid solution works by reacting with the free lime in the concrete. This causes a breakdown of the calcium at the surface which exposes the open pores of the concrete. This calcium is then deposited onto the surface in the form of a very fine white dust.

Many epoxy floors have peeled up because this fine white dust was not effectively removed before the epoxy was applied.

Because the dust is so fine, it likes to stick to the irregularities in the surface and can be difficult to remove. If epoxy is applied over concrete with this fine white dust, the epoxy sticks more to the dust and not the surface. It will eventually peel up exposing the white dust on the underside of the peeled epoxy coating.

The amount of dust left on the surface after acid etching is dependent on how much free lime was present in the surface of the concrete to begin with and how well the floor was neutralized and flushed afterwards.

Never let the floor start to dry during the acid etching process and use liberal amounts of water when flushing the surface. It helps to use a deck brush to lightly scrub the surface as it is being flushed. If you end up with this white residue it can be removed, but it may take multiple scrub downs to get it all off the surface.

A pressure washer works best. If you don’t have one available, wet the floor down in sections and use a solution of TSP and hot water to scrub the surface. Flush it well with a high pressure nozzle and move on to the next section. It will come off, but it may take a few tries.

5. Sealed Concrete

Epoxy will not adhere to concrete that has been previously sealed and acid etching will not remove a sealer. As we have stated previously, acid only responds to the free lime in concrete. If the concrete is sealed, the acid etch solution will just sit on the surface and not do anything. More than one case of epoxy peeling has been from people attempting to acid etch a sealed garage floor.

The only way to profile a previously sealed garage floor correctly is to grind it. Grinding the floor will remove the sealer at the surface and profile it at the same time.

If you are not sure if your floor has a sealer, then you need to do a concrete sealer test. Do this by dripping water over various areas of the concrete. Does the water immediately bead up or just sit there for a few minutes without being absorbed into the concrete? Then you have a sealer on the garage floor.

If the concrete turns dark and the water is absorbed after a few minutes, then you don’t have a sealer on the floor.

Are your tests are inconclusive? Apply a few drops of diluted muriatic acid to the surface. If it starts to bubble and fizz, then no sealer is present. If it just sits there like a drop of water and does nothing, then the concrete is sealed.

6. Excess Laitance

Laitance is a weaker top layer of cement. Sometimes it can have a crazed look to it with what appears to be very fine cracks. It consists of a fine cement paste top layer that is produced by excess bleed water when troweling the finish. It can also be caused by concrete finishers who spray water on the surface of the concrete to make it smoother.

Grinding the concrete will remove this fine layer and prep the surface properly for epoxy. Acid etching on the other hand will not do this very well. It will only rough it up. What you end up with is a softer concrete surface that is not bonded well to the rest of the concrete.

When epoxy is applied to this type of surface, it creates a weak mechanical bond to the concrete that can eventually cause it to peel up at a later date. Concrete dusting is a sign of excess laitance and sure indication that you should grind the garage floor to get the proper profile.

7. Soft Concrete Surface

A soft concrete surface can be caused from poor concrete, bad finishing or a combination of both. Indications of soft concrete include heavy surface dusting, areas that are easily scarred or gouged, and crumbling concrete.

The only solution to a soft concrete surface is to grind it. It may also require application of a densifier to harden the surface. Sometimes even that will not prepare the concrete properly for epoxy.

If you have a soft concrete surface, we recommend contacting a professional floor coating company or installer to inspect the surface and do the job for you if they deem it feasible. If you are looking for a DIY garage flooring installation, then interlocking tiles or garage floor mats may be a better solution for you.

Click the button below to choose

your date and time!

FINAL TIPS

One thing to remember is that the lesser expensive garage floor epoxy kits will eventually wear out in high traffic areas. This is not the same as peeling. You will notice that the floor in these areas will become dull and the concrete will start to show through. This is a result of abrasion at the surface of the coating and not from peeling.

Hot tire pickup is not necessarily a sign of bad floor prep either. Again, the lesser expensive epoxy products can be prone to this no matter how well the floor was prepared. The reason is due to the low solids content of the epoxy as well as the chemical makeup.

Applying a successful epoxy garage floor coating that does not peel truly is not that difficult. It just requires some attention to detail and knowledge of how your garage floor concrete should be prepared and tested before application.

With the exception of moisture issues, most of these common problems with epoxy peeling can easily be avoided just by grinding the garage floor.

However, whether grinding your floor or acid etching, if you pay close attention and follow these tips you should have a successful epoxy coating that will not peel after application.